Only 6 Months Left! Is Your QMSR Compliance on Track?

QMSR Countdown: Just 6 Months to Compliance

On February 2, 2024, the U.S. Food and Drug Administration (FDA) introduced the Quality Management System Regulation (QMSR) and the purpose of this regulation is to align the ISO 13485:2016 standard requirements with the medical device quality management system (MD QMS) requirements of 21 CFR Part 820. With the publication of the final rule, the FDA has provided further clarification and guidance to help manufacturers begin planning their implementation strategies in advance of the effective date, February 2, 2026, exactly six month from today.

What are the key changes introduced by the Quality Management System Regulation (QMSR)?

1. Key Changes in QMSR:

- Risk-Based Approach: QMSR integrates risk management throughout the product lifecycle.

- Audit Transparency: Previously, some internal audit and management review reports didn't have to be shared with the FDA. Now, those exemptions are removed. This means companies must be more open and ready to share these reports with the FDA. The new rule is similar to what ISO standards already require and could change how companies plan and conduct their internal audits.

- Terminology Updates: The FDA QMSR introduces updated terminology, such as replacing “management with executive responsibility” with “top management,” and changing “device master record” (DMR) to the broader term “medical device file.”

2. ISO 13485 Included “By Reference” (Section 820.7):

The updated Section 820 of 21 CFR now includes ISO 13485:2016 by reference. This means the FDA considers ISO 13485;s requirements to be mostly aligned with its own. As a result, manufacturers already following ISO 13485 are largely meeting FDA expectations.

However, the FDA has set limits on this alignment:

- If ISO 13485 is updated in the future, the new version won't be automatically accepted. The FDA will first review the changes to decide if U.S. regulations also need to be updated.

- The FDA did not adopt ISO 13485 exactly as it is. Instead, it made modifications to ensure consistency with other FDA regulations. Because of this, manufacturers must still comply with some additional or different requirements.

Note: Having ISO certification alone is not enough for FDA inspections.

Even if a company is ISO 13485:2016 certified, it must still ensure that its quality system meets the specific requirements of the FDA's QMSR. The FDA will continue to conduct its own inspections and require Establishment Inspection Reports (EIRs), as mandated by U.S. law.

How FDA QMSR differs from ISO 13485:2016?

A. New Definitions:

The FDA has added new definitions in the QMSR—such as “Component,” “Finished Device,” and “Remanufacturer” - which are not found in ISO 13485. The QMSR also updates definitions for terms like “Implantable Medical Device” and “Manufacturer” to better align with FDA requirements. It also ensures that terminology for combination products aligns with current Good Manufacturing Practice (CGMP) standards.

B. Control of Records (Section 820.35):

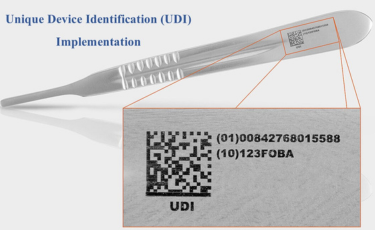

The QMSR requires companies to manage certain records carefully in accordance with the FD&C Act. This includes maintaining proper records of complaints, service activities, and compliance with rules for Medical Device Reporting and Unique Device Identification (UDI).

C. Labelling and Packaging (Section 820.45):

The regulation strengthens control over labelling and packaging processes and ensures oversight of manufacturer label inspections, as required by ISO 13485:2016.

What Immediate Actions Should manufacturer Take to Prepare for QMSR Enforcement?

- Conduct a comprehensive QMSR gap assessment against your current ISO 13485 system

- Update quality documentation, SOPs, and policies to reflect FDA-specific terminology and expectations

- Train your teams on the key changes introduced by QMSR

- Ensure audit documentation and management review processes are ready for FDA inspection

- Engage regulatory experts if there is uncertainty about how QMSR differs from ISO

Key Takeaway:

The QMSR introduces several important differences from ISO 13485:2016. As a result, manufacturers cannot rely solely on their ISO certification to meet FDA requirements. The FDA has made it clear that ISO compliance alone is not enough—companies must also meet the additional, specific requirements outlined in the QMSR. This makes it essential for manufacturers to proactively update their quality management systems to fully align with the QMSR—even in areas not covered by ISO 13485. The required changes may involve more than minor tweaks and could demand major updates to processes and documentation. Starting early will help ensure a smooth transition and continued FDA QMSR compliance in an evolving medical device market.

Need Help?

We offer support with:

- QMSR gap audits

- SOP and documentation updates

- Internal training and audit preparation

- FDA inspection readiness planning

Let us help you turn compliance into confidence. Contact us today

Share this blog

Read More Blogs

Medical Device Approval Process in Japan | PMDA and MHLW Guide

Saudi Arabia Medical Device Approval | SFDA Regulations

Unique Device Identification Made Simple with V-Reg Solutions